Weber, president of Rego-Fix Tool Corp., Indianapolis. “A CAT or BT holder has keyways at the flange that transmits torque,” said Andreas S. The polygon also provides torque transmission from the machine tool spindle to the cutting tool without the need for keyways. The polygon taper ensures automatic radial centering and even pressure around the coupling, according to Sandvik Coromant, enabling repeatability within 2μm. “I found the three-sided polygon provided superior stability.” “Why does a modular system have to be circular?” Andersson asked.

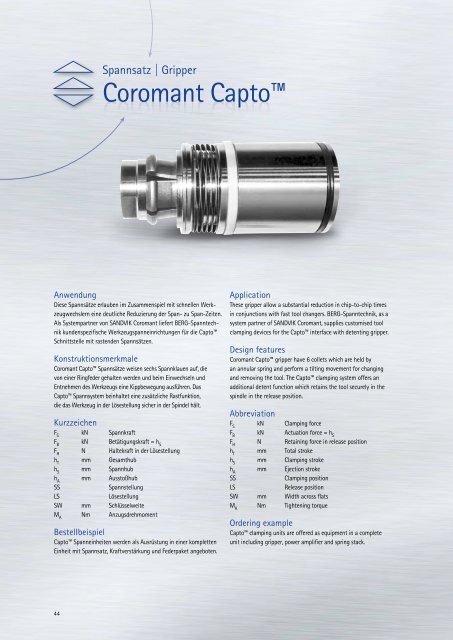

The Coromant Capto’s three-corner polygon shape distinguishes it from other toolholders.

COROMANT CAPTO ISO

We drove this certification to make sure no one could change the design, and that’s what ISO certification achieves.” “We wanted to ensure that if anyone makes it, and anyone is more than welcome to make it, all the tolerances are exactly the same as the original. “When the patent ran out, we didn’t want people to make a lower-quality version so that it started to create problems for those who had Coromant Capto,” said Chris Mills, national portfolio manager for Sandvik Coromant, Fair Lawn, N.J. Sandvik Coromant’s Coromant Capto machine adapted clamping units (MACU) for lathes are suitable for turning and milling applications. ISO certification means no manufacturer can sell a Coromant Capto holder that doesn’t conform to the standard’s specifications.

COROMANT CAPTO LICENSE

Since then, Coromant Capto has made industry inroads via sales by Sandvik Coromant and its various licensees and was adopted in 2008 as an ISO standard (26623) for toolholding systems when the company’s patent expired and the need to license it ceased.

COROMANT CAPTO FULL VERSION

Sandvik Coromant completed the first prototype in 1989 and unveiled the full version at IMTS 1990 in Chicago. Ken Andersson, who has since retired from the toolmaker and now builds boats, invented Coromant Capto. For the Coromant Capto toolholding system developed by Sandvik Coromant Co., modularity, universality and repeatability define it. Those are definitions of the Latin word capto. It provides flexibility and speeds up the changes of tool for machines multitarea, lathing centres and machining centres.A look at the Coromant Capto modular toolholding system. The attachment Coromant Attract constitutes a system auténticamente modulate, that allows a total intercambiabilidad of tools between the distinct machines of the workshop, with the consequent reduction of inventory and of cost. Available also pieces in the rough to manufacture of agreement to the needs of the customer for a greater flexibility. It finds available a complete range of tools in size C10, that includes so much the basic handles like the adapters of reduction and extension.

This big size of attachment confers a maximum stability to the tools of tornear and mill, as well as a big rigidity for long settings used jointly with adapters of reduction to adapt to the tool. It presents a greater resistance to the flexión and allows a greater speed of start of shaving, with a greater precision in the area of application. This attachment has a diameter of brida of 100 mm and transmits the pair torsor with big efficiency. It allows to achieve greater advances and depths of cut, especially in the mechanised of pieces for the aerospace sectors, of turbines of gas and of turning of wheels of railway industry. The attachment Coromant Attract of size C10 is designed to improve the performance in demanding applications with machines-tool of big size.

0 kommentar(er)

0 kommentar(er)